Do not overengineer

I have been working with different engineering teams for years, and the only thing that has been common to most of them is that they tend to overengineer. The interesting fact, though, is that the engineers themselves are rarely the real root cause of the problem.

First, what is overengineering? A disposable item built to withstand thousands of cycles, an 8-channel amplifier where you only needed two, and so on. I even saw a technical founder who attempted to bring the same SW development processes he used to have in Google to a 15-person startup (didn't end up well). Something that is designed to be too complex or too robust for the given purpose.

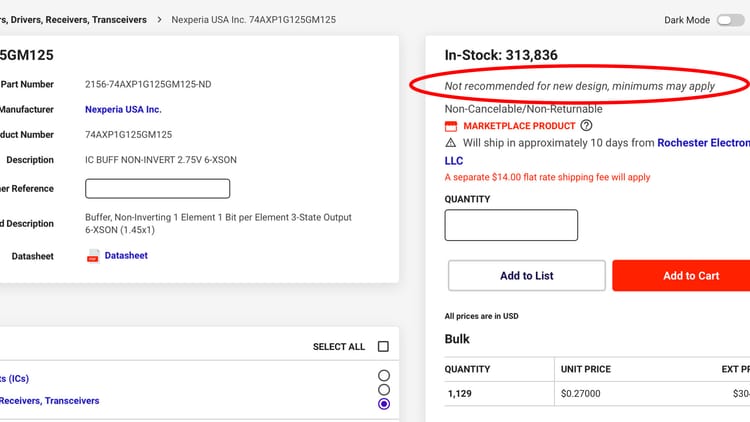

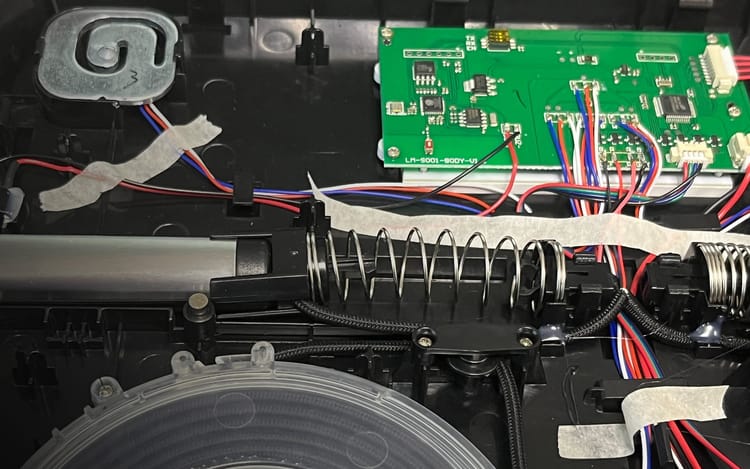

The engineers' logic is simple: they genuinely want to make better things. From the engineer's perspective, the better IC is always better, and the more robust part is always preferable. And almost always, they want to make the product future-proof. Built for bigger loads (in SaaS), use the same platform for future uses (hence more options/capacity built in the logic board).

When the product management (or founders) do not give the engineers enough constraints, such as the target BOM cost, or if they don't emphasize the need for simplicity... The engineers start building "better" things. "Better" does not mean things that are needed.

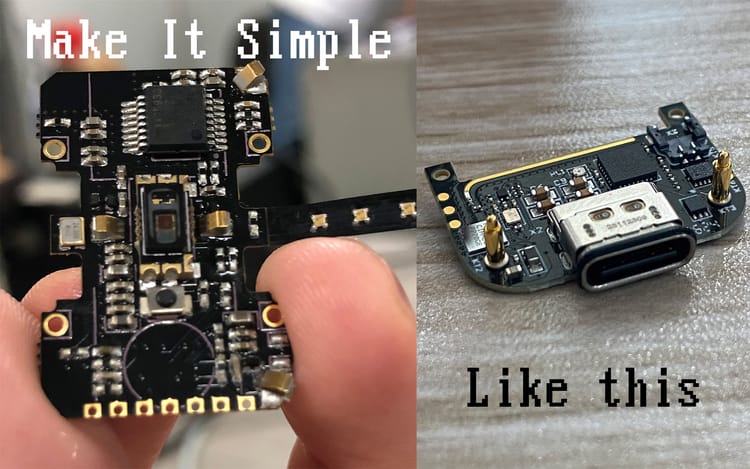

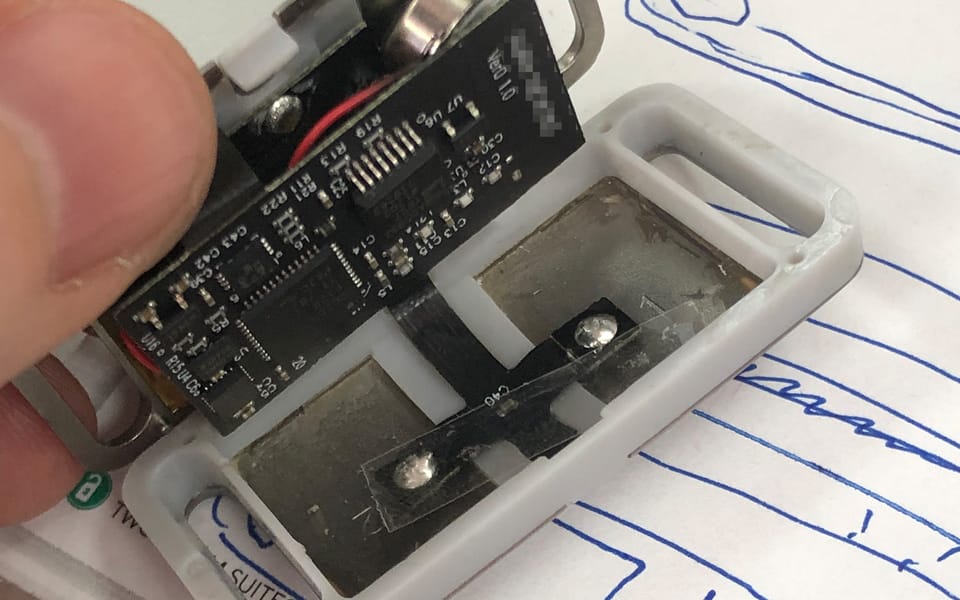

You don't need to build infrastructure capable of rapid scaling to millions of visitors per day when you only have a few thousand per month. You don't need the expensive IC for your logic board if you don't use half of its features. You definitely don't need a sintered part with PVD coating when you can get the same look and feel with just stamped stainless steel.

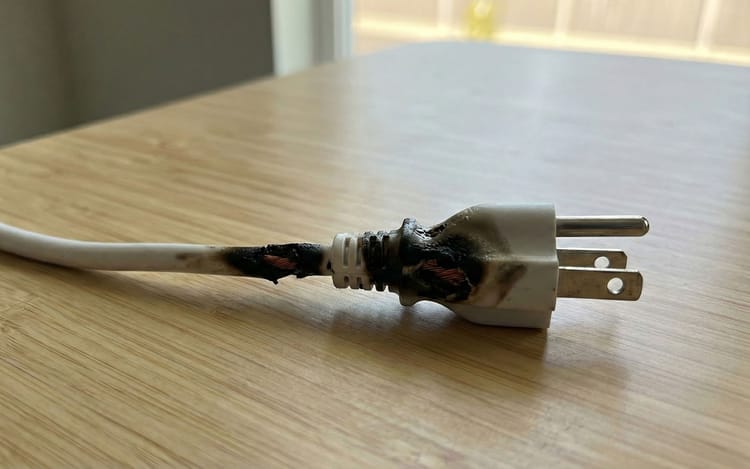

The simple solutions sometimes (but not always) compound a so-called technical debt. This is more likely for the software products, where the reuse of existing components is much more common than in hardware. But overengineering generally causes even more problems for startups.

Startups must be lean and fast. When something is not working, startups pivot and try another approach. The production cost must be as low as possible. Overengineering is exactly the opposite of that.

So, what can you do as a founder/CEO? It's very simple:

- Give engineers constraints: target BOM cost, development deadlines, manufacturing parameters (e.g. max time per unit during assembly)

- Ask engineers to prioritize cost and simplicity, and explain why the cost and simplicity matter

- Do not hide the unit economics from the engineering team, so they see the impact of their cost optimization efforts

Give your engineer constraints and don't let them fly blind. More constraints for engineering mean a better product.

Be lean and fast.