G01 MOQ: Minimum Order Quantity

Your supplier just quoted you 3,000 units minimum. You only need 500. Now what? Don't walk away or order 3,000. Here's what I'd do.

MOQ stands for Minimum Order Quantity: the smallest number of units a supplier will manufacture in a single production run.

Think of it like this: if you walk into a bakery and ask them to bake you three custom wedding cakes, they might say yes. But if you call a commercial bakery that makes thousands of cakes per day and ask for three, they'll probably say no. The setup time, machinery changeover, and administrative work simply isn't worth it for such a small batch.

Why MOQ exists:

Manufacturers have real costs every time they start a new production run. They need to:

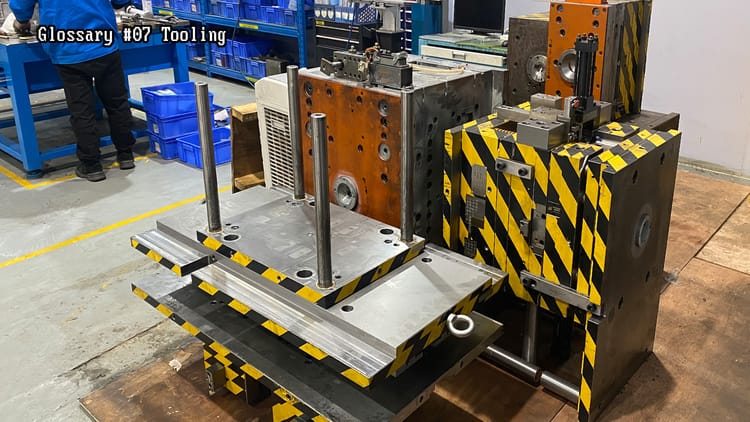

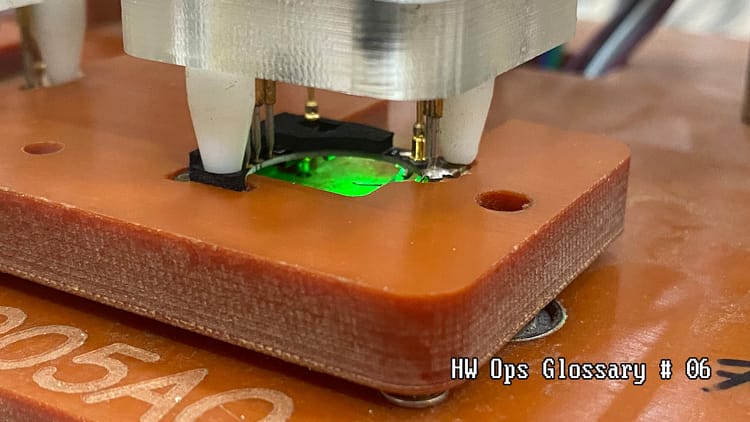

- Set up and configure machinery for your specific product

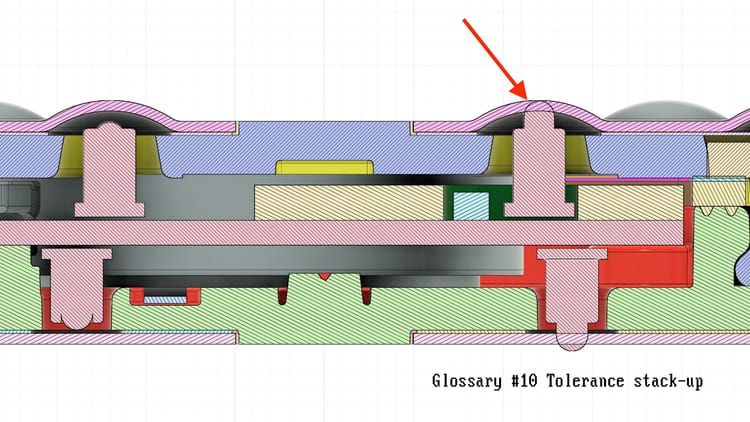

- Set up tooling and NRE (stencils, fixtures/test jigs, molds/dies) needed to run your build

- Order components (which often have their own MOQs)

- Allocate warehouse space and logistics

- Handle administrative overhead

For a factory making 50,000 units per month, stopping the line to make 200 units of your product costs more in lost productivity than they'd make from your order.

Here's the critical part most founders miss:

Always ask about MOQ in your first conversation with any supplier. Not after you've spent weeks on samples. Not after you've designed around their capabilities. In the first email. This saves everyone time and helps you build a realistic production plan from day one.

When a supplier's MOQ is too high, you have four options:

- Ask nicely (and strategically) Explain you're a startup, this is a pilot run, and you're planning to scale. Some suppliers—especially those looking to build long-term relationships—will make exceptions. This works better than you'd think, particularly if you're professional and clear about your growth plans.

- Pay a "below MOQ" fee Many suppliers will do smaller runs if you pay a fixed setup fee. You might pay $500-$2,000 to cover their setup costs, then pay the normal per-unit price. Do the math: sometimes this is your best option for initial production.

- Accept a higher unit price Suppliers might agree to lower quantities if you pay more per unit. Your $8 component might become $12 for a 500-unit order versus their 5,000-unit MOQ. For a pilot run, this premium is often worth it to prove your product works.

- Buy the components that drive the MOQ Sometimes the MOQ isn't about your product, it's about a specific component the supplier needs to order. If they need 10,000 of a particular chip or connector, offer to buy all 10,000 upfront. They manufacture what you need now, and hold the extra components for your future orders. You get your pilot run, they get certainty about future business.

MOQ isn't a wall, it's a negotiation. But you can only negotiate if you ask early and understand what's driving the number.