In hardware, "undefined" means "expensive"

Your OEM sample might be a real production unit... or a bench Frankenstein.

Two reasons you ask an OEM supplier for a sample, and why the word "sample" is not as simple as it seems.

- Supplier assessment

You want to judge the factory's product and decide if they are even worth talking to. This is usually a one-off encounter. If the sample is bad, you move on (unless the supplier is truly unique). - Building your own product

You are ready to perfect your product. A bad early sample is not a show-stopper. It is just feedback. You simply iterate (often, for months) until the product is acceptable.

In BOTH cases, the critical thing is alignment:

What kind of sample is this?

A "sample" can be:

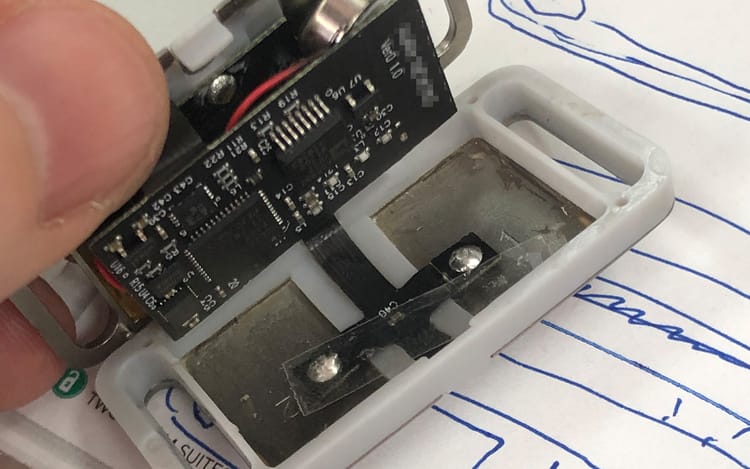

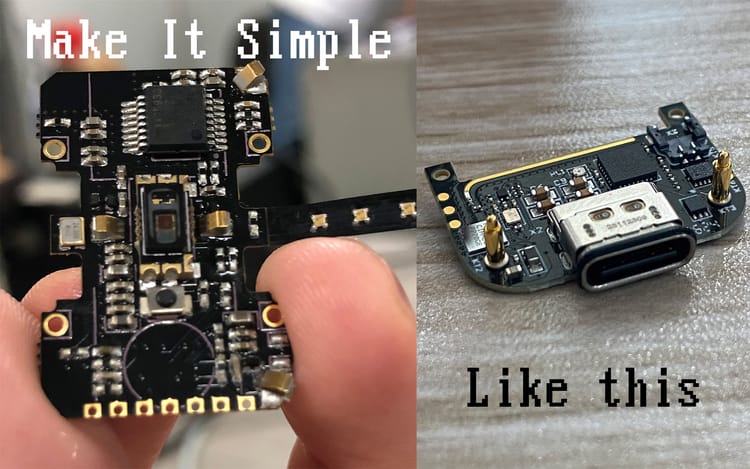

- Production-grade: pulled from real mass production (or built on the line with the same jigs, test fixtures, firmware, process parameters, and the final BOM + approved alternates)

- Engineering / bench build: hand-assembled from whatever parts are available, sometimes leftovers, reworked boards, or substitutions

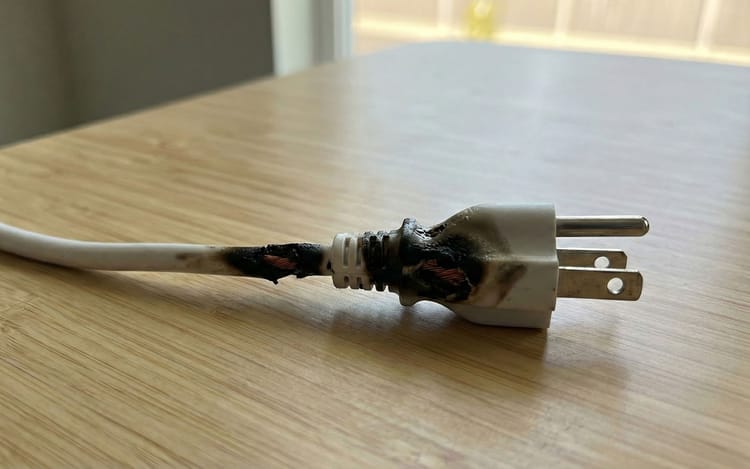

Neither is automatically good or bad. The problem is when you think you are looking at one, but you are actually getting the other.

If you are evaluating build quality, cosmetics, reliability, or yield risk, request a production-representative sample in writing. If mass production is not running yet, the factory should say so and label it clearly.

Quick sanity checklist: serial number, build date, BOM revision, firmware version, and a short test report. If possible, ask for a photo of the unit at the test station or on the line.

But if your goal is features, UX, or software flow, a lower-grade engineering sample can be totally acceptable. In that case, demanding "mass production quality" can be a waste of time and money.

In hardware, “undefined” becomes “expensive.” Very expensive. Define the sample, or the sample defines your future.