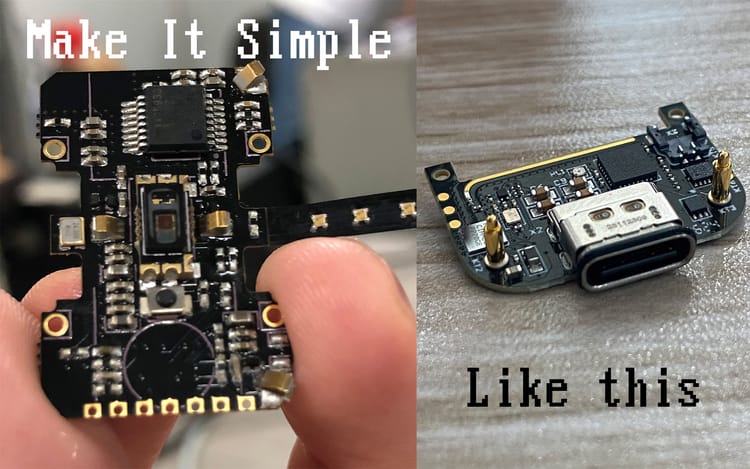

"The US version is easy"

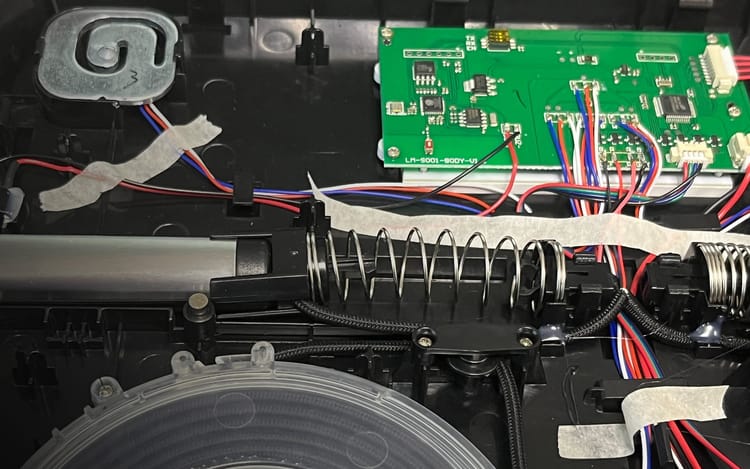

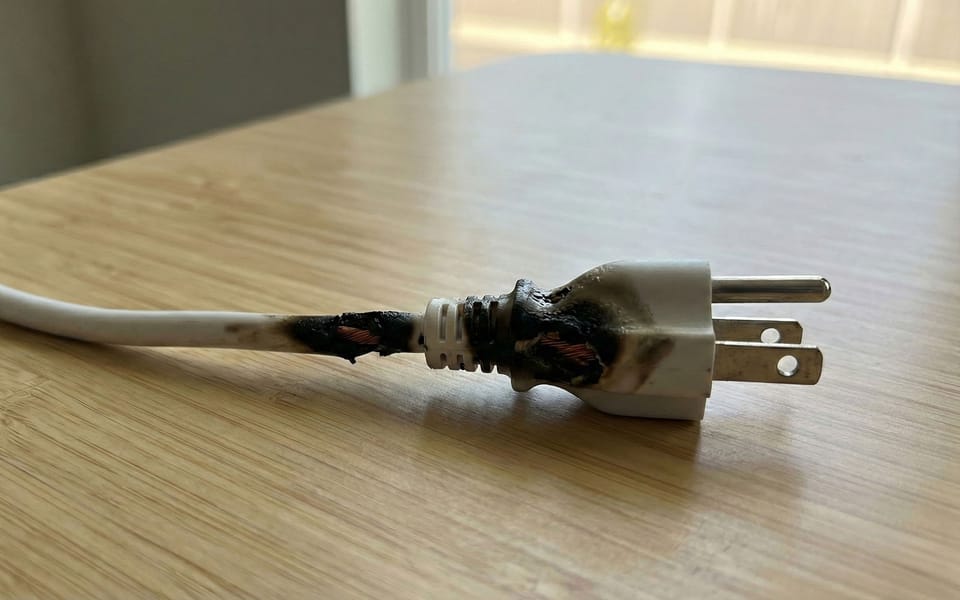

Your factory told you "US version is easy." If you believed it, the same thing as in the photo is your next surprise. Here is why.

This failure usually starts with a decision you never see: the factory reuses what already works for their domestic builds.

If your supplier mainly ships to 220V markets, they may treat the cordset/internal harness as a generic commodity. And because the plug shape fits, the same cordset can quietly end up on the US batch.

China is ~220V. The US is ~120V.

Same watts, lower voltage means higher current.

Take a real-life example: 1500W (heater/kettle/hot plate).

That is ~6.8A at 220V, but ~12.5A at 120V.

Heating at a weak point goes as I^2R.

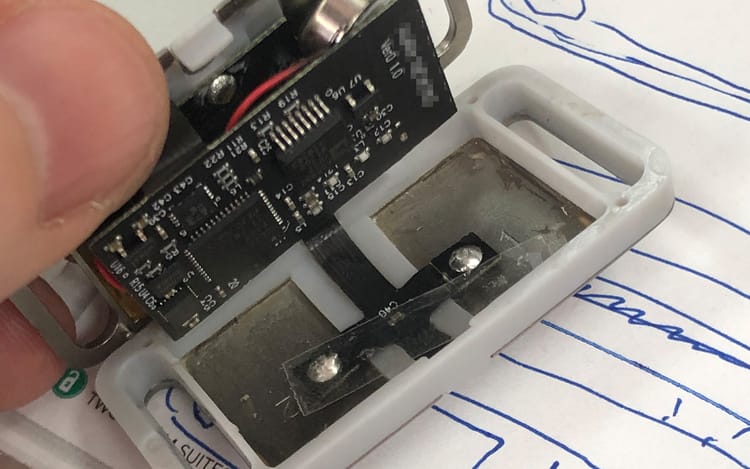

So ~2x current can become ~4x heating at the worst place: a marginal crimp, a tired strain relief, or a loose outlet contact. It will still pass a quick functional test. Then it fails under sustained load in the field.

The US version is not "the same unit with a different plug". It needs a cordset spec and test plan that matches 120V current.

What I would check if I were making a product for the US market:

- Compute worst-case amps at 120V (steady-state + inrush/peaks)

- Freeze the cordset/harness spec in the BOM: AWG, temp rating - exact part (no "equivalent")

- Require US-rated/listed cordsets/materials (UL/ETL/CSA as applicable) and verify markings on the actual part

- Lock specs: no substitutions without written approval

- Incoming spot check: cut one sample and confirm AWG/strand count matches spec

- Full-load thermal soak (hours) at worst duty and warm ambient, then measure temp at the plug, strain relief, crimps/connectors. Check for heat damage

Hardware is hard enough without risking a fire because of a $0.50 cord decision.